In addition to our workbenches in Eskişehir Design and Innovation Centre, we will also offer the MEGEM infrastructure to the service of our SMEs with whom we cooperate. MEGEM includes CNC machining centres, welding workshop, CMM and mechanical testing laboratory.

CNC Turning Machine

TL 200 model of LOKESH brand (Figure 1). CNC Turning Machine is a single turret, 2-axis lathe. The maximum part dimensions that can be processed on the machine are Ø 260 mm x 258 mm. The machine has features such as spindle speed 3700 rpm, position accuracy 0.006 mm and repeatability accuracy 0.005 mm.

CNC Milling Machine

It is the VM740S model of the NEWAY brand (Figure 2). The machine is a 3-axis milling machine. The maximum part dimensions that can be processed on the bench are 650x420x500 mm and its weight is 350 kg. The machine has a maximum spindle speed of 10000 rpm, position accuracy of 0.008 mm and repeatability accuracy of 0.005 mm.

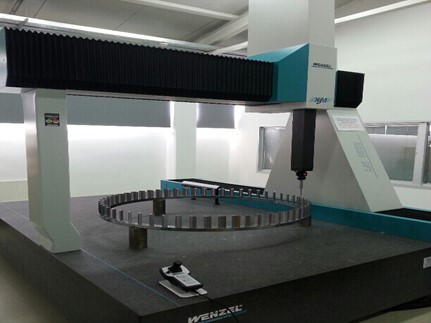

Measurement and Testing

There is a CMM device in order to determine the measurement accuracy of the parts produced in MEGEM. WENZEL brand LH 1512 model CMM device (Figure 3) performs measurements of parts with maximum dimensions of 1400x2000x1200 mm and a weight of 3500 kg.

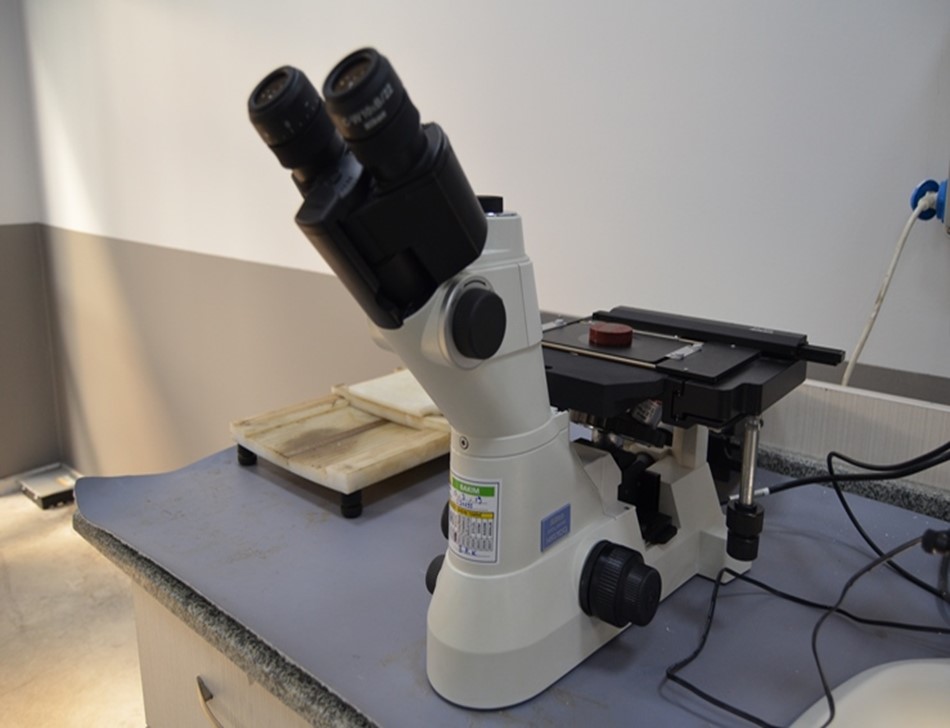

In the test laboratory, there are tensile, charpy impact test, vickers hardness measurement, microscope and spectral analysis devices. In addition, the necessary sample preparation tools are also available in the laboratory in order to prepare suitable parts for test equipment. The tensile test is performed on the Alşa brand MCK 600 model device (Figure 4). It can apply tensile force up to 600 kN. The tensile tester has hydraulic clamping. Round materials with a diameter of 6-40 mm and flat materials with a thickness of 0-30 mm can be connected to the test device. The tests that can be performed on the device are tensile, compression, bending, holding in the load.

For the charpy impact test, the Alşa brand 300J (Figure 5) model is located in the laboratory. The fall speed of the test device is 5.5 m/s, and the fall angle is 160°. Thanks to the cooling cabinet in the laboratory, experiments can be carried out down to -40°.

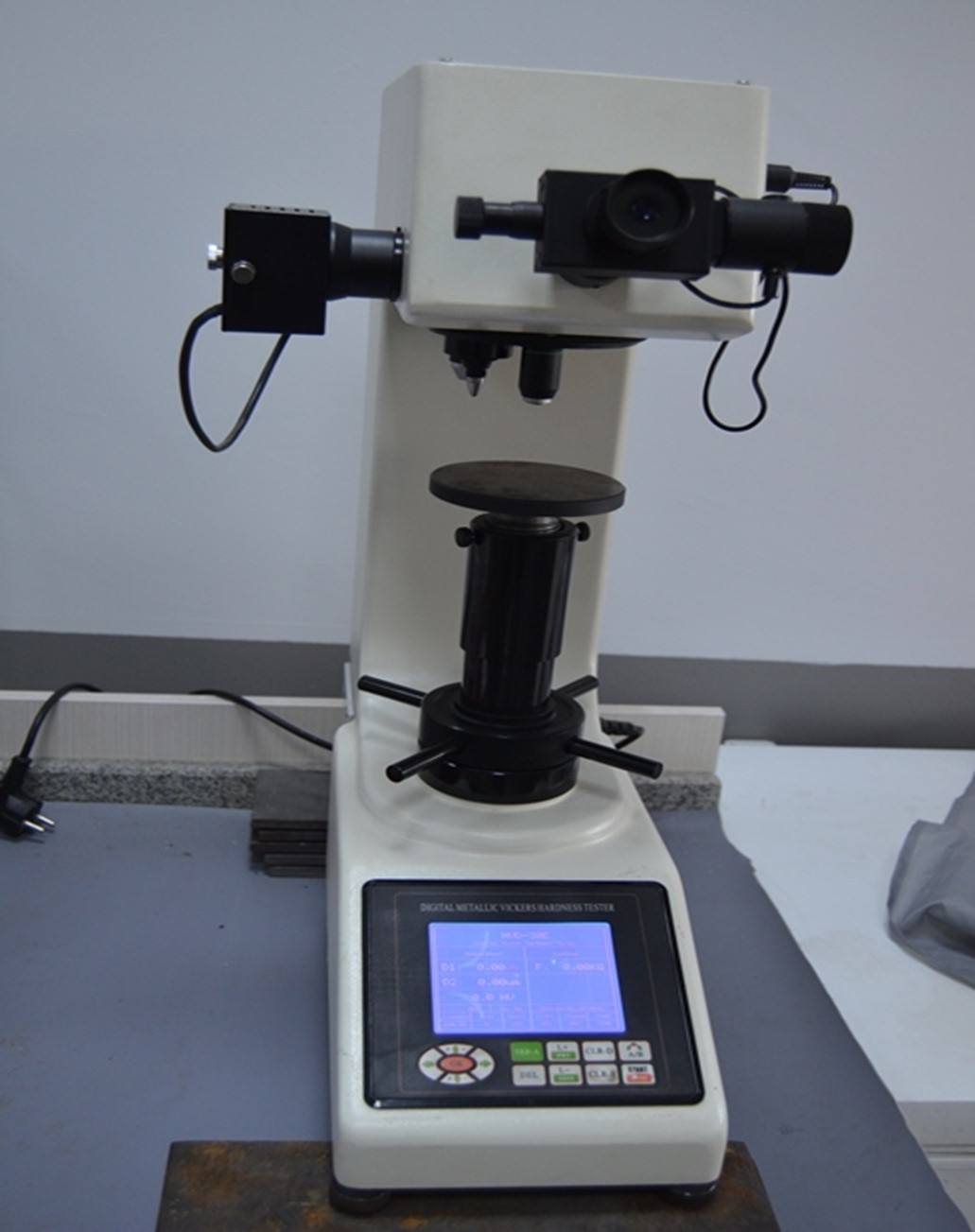

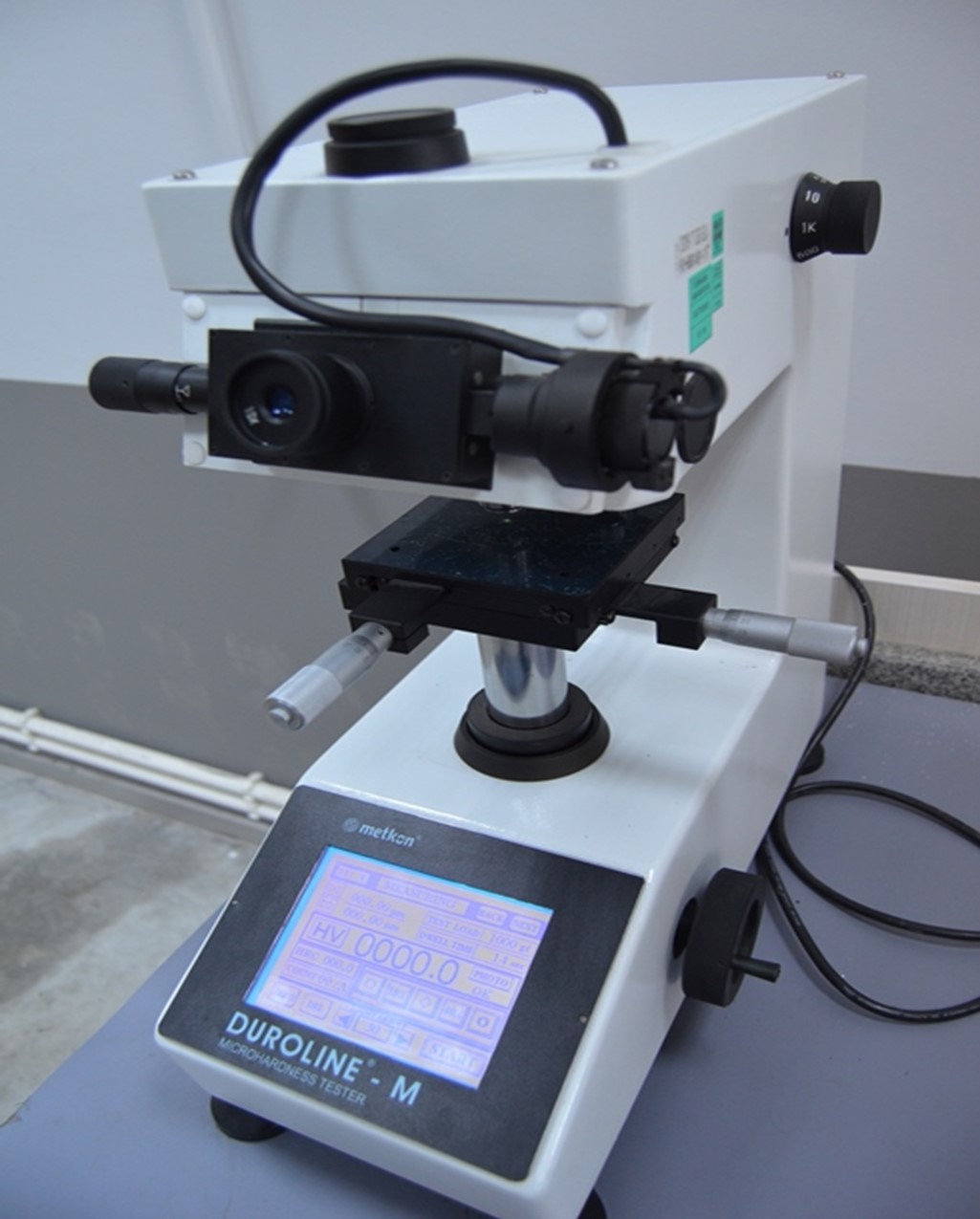

There are macro and micro hardness testers to measure the hardness of the parts. The macro hardness tester is the Duroline-V (Figure 6) model of the Metkon brand. It measures hardness using the Vickers method. The device can measure the vickers hardness of products under a load of 1,2, 3, 5,10,20,30 kg.

Welding Workshop

MIG/MAG, electric arc welding and TIG (argon) welding can be done in MEGEM.

For MIG/MAG welding, Rs400MW (Figure 11) of Magmaweld company is used. The welding machine working with 3 phase 400 V allows current adjustment between 45 400 A. The wire feeding mechanism, on the other hand, provides the opportunity to feed the material with a diameter of 0.8 – 1.6 mm.

Monostick 200i model (Figure 12) welding machine of Magmaweld company is used for electric arc welding. The welding machine working with 1 phase 230 V allows current adjustment between 10 200 A. It allows welding with material with a diameter of 1.6 – 4 mm as an electrode diameter. It has excellent welding characteristics for Rutile and Basic electrodes.

Monotig 200i model (Figure 13) of Magmaweld company is used for TIG (argon) welding. The welding machine working with 1 phase 230 V allows current adjustment between 5 200 A. It allows welding with 2 – 4 mm diameter wire material.

In the welding workshop, there are also a 100 ton Hidrosan HD 100 workshop type press (Figure 14), Keke KMO 220 fully automatic articulated band saw (Figure 15) and Saymak SGM 1020 heavy-duty guillotine shear (Figure 16).